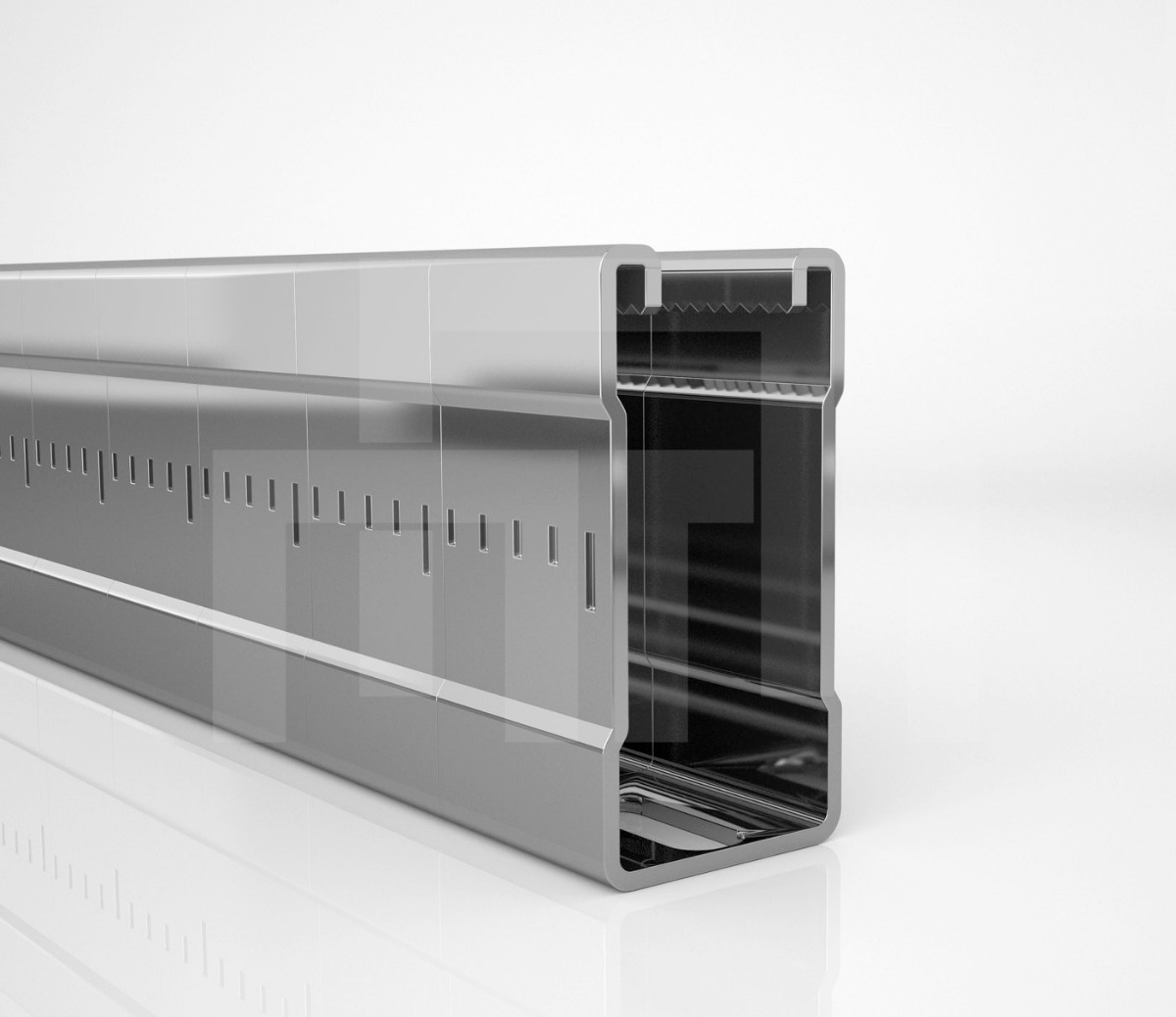

Special Open Section Profiles

- Maximum sheet thickness that can be formed: 8mm

Maximum bandwidth: 1000 mm

Open profiles made of galvanized, hot, cold, painted, magnelis sheet

Production in desired length Drilling, shaping and bending processes before or after profile

Special profile production in every desired cross section and construction of all mechanical processes depending on the profiles.

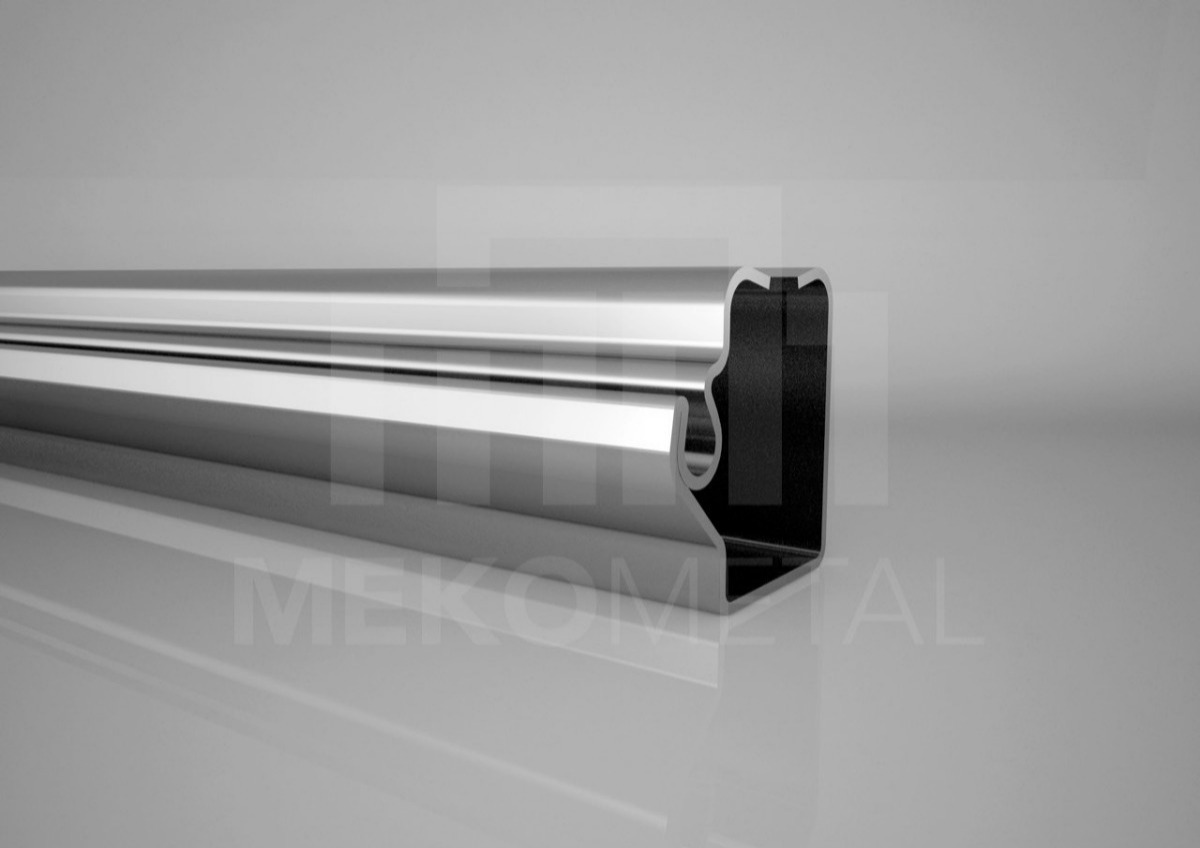

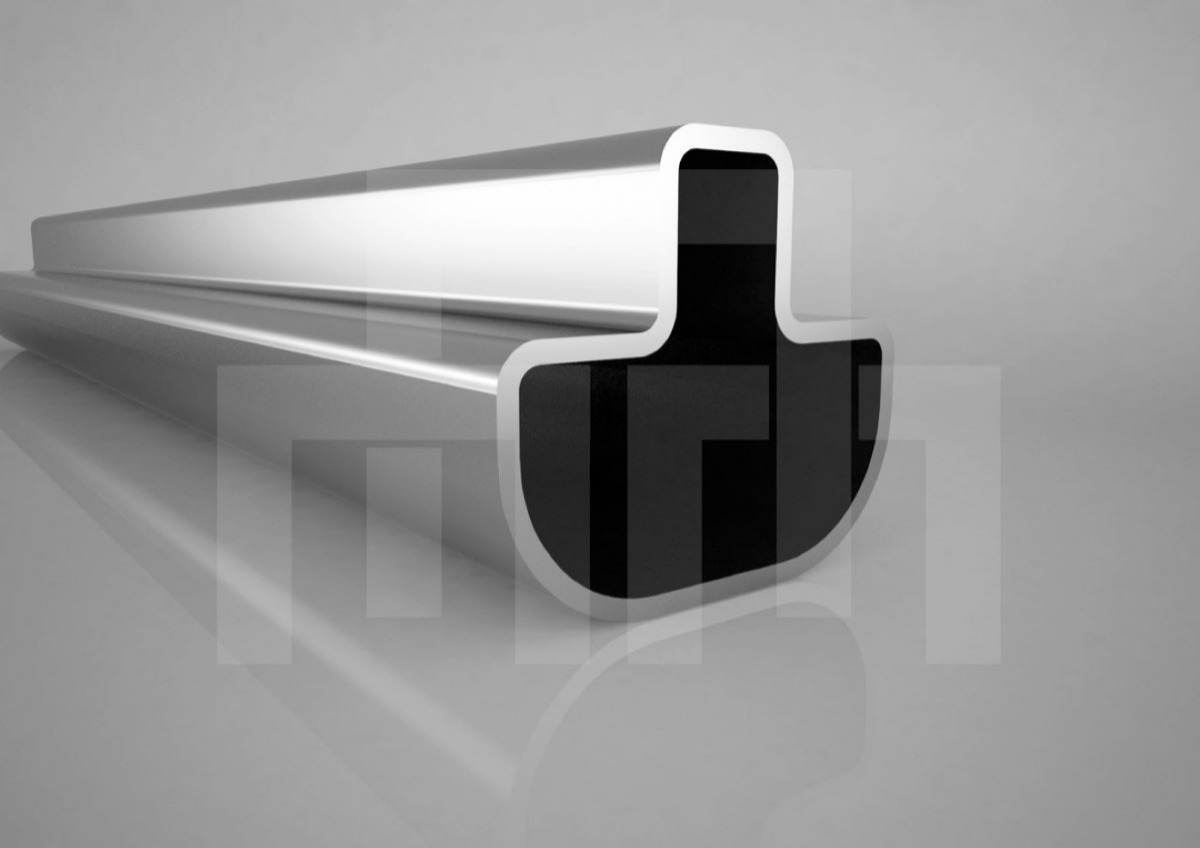

Clamped Profile Production

- Maximum sheet thickness that can be formed: 4mm

Maximum bandwidth: 500 mm

Galvanized, hot, cold, painted, magnelis sheet metal clamped profiles

Can produce in any desired lengths

Drilling, shaping and bending processes before or after profile

Special profiles can be produced in every desired cross section and constructed using a variety of mechanical processes depending on the profiles.

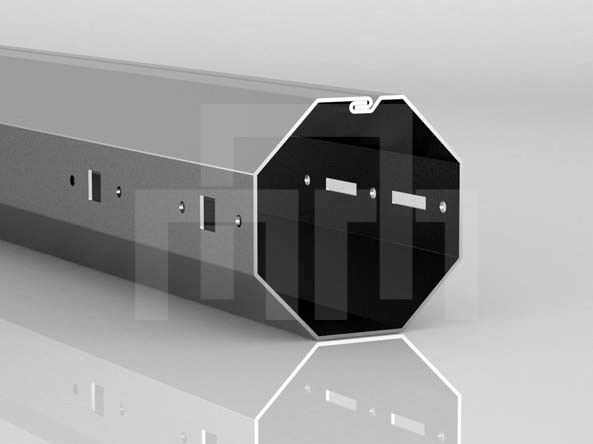

Stitched Special Profile Production

- Minimum and maximum sheet thickness: 0.4 - 8 mm.

Pipe production diameter Ø10 - Ø193 MM profile production range 10*10 - 150*150 galvanized profile production, re-coating the welding place with zinc, profile production in special sections in welded profile, drilling and cutting operations before or after profile drawing.

Bending and mechanical processes after shaping.

Shooting any desired brand on the profile.

Profile cutting, drilling, bending, shaping and assembly applications.

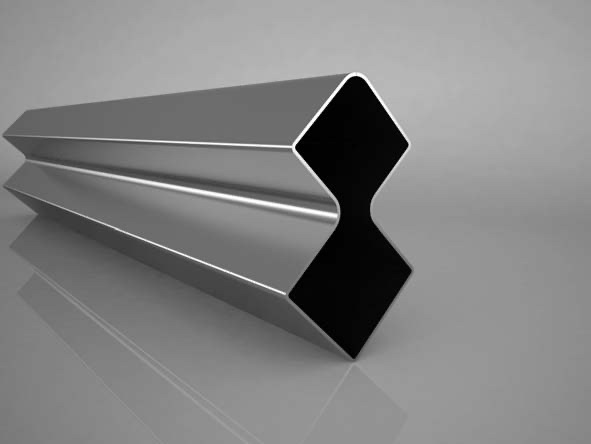

Cutting - Punching - Bending Welding Applications

Our various production lines are capable of bending standard tubes and profiles. Cutting and punching is available for all profiles by using special templates, or if it is necessary, by hydraulic or pneumatic machines that can be designed and produced in-house. CNC saws can also be used to cutting profiles to various requested lengths.